Ceramic Pall Ring Company

Ceramic pall ring can be used in high or low temperature conditions.It can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers.

H1 Ceramic pall ring Chemshun Ceramics

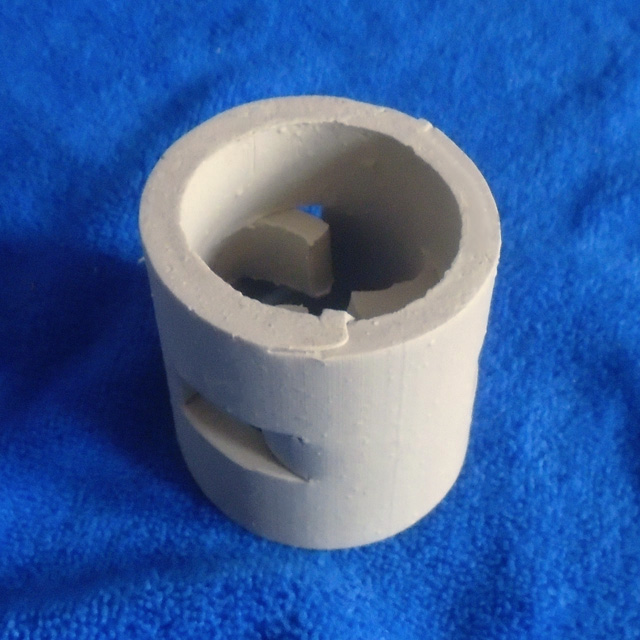

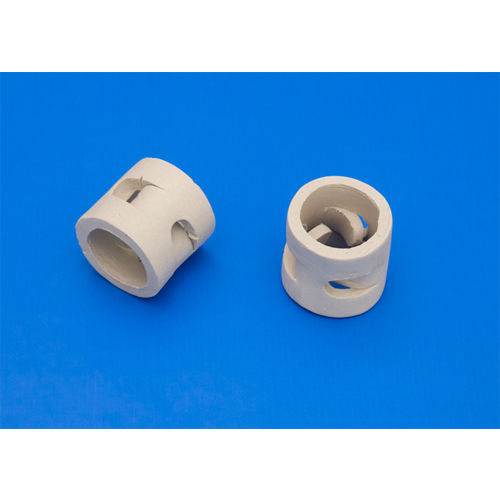

1. Description Ceramic Pall Ring is a kind of new type and high efficient packing that is improved on the basis of the Rasching ring. Chemshun pall ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings. The opened cylinder walls and inward bent protrusions of the Pall Ring allow.

Ceramic Pall Ring Company

The pall ring is the industry standard, the most commonly used random packing type. The design of the pall ring is an improvement of the raschig ring. The cylinder walls are punctured. This adjustment provides a significant performance increase, resulting in an improvement of the capacity and efficiency. In addition, this adjusted design leads.

Ceramic Pall RingOIM Chemical

Raschig rings one inch (25 mm) ceramic. A Raschig ring is a piece of tube, approximately equal in length and diameter, used in large numbers as a packed bed within columns for distillations and other chemical engineering processes. They are usually ceramic, metal or glass and provide a large surface area within the volume of the column for interaction between liquid and gas vapours.

Ceramic Pall Ring for Extreme Corrosion Chemical Industry China

Ceramic pall rings are executed with side openings which improves the separation efficiency and thus facilitate a more effective mass transfer. The pressure loss in the process is even further reduced due to moderate gas deflection. The capacity characteristics of the ceramic pall rings are more c onstant in comparison with the

Ceremic Ceramic Pall Ring at best price in Pune ID 23666588273

Ceramic Pall Ring is improved from the ceramic Raschig Ring, Ceramic Pall Ring has add a design of open the holes for the weeks wall, this construction can improve the surface area and voidage, Ceramic Pall Ring makes porosity distributed even and improves the distribution of the fluid, greater capacity and lower pressure drop than ceramic.

Ceramic Pall Ring

Ceramic pall rings: Ceramic is known for its brittleness, making ceramic pall rings less common than plastic and metal pall rings. However, ceramic pall rings provide excellent organic solvent resistance and chemical stability. Pall Ring Applications. Pall rings range in size and configuration to provide optimal flow for various applications.

Pall Ring for Acid Resistance Ceramic Tower Packing China Pall Ring

Ceramic Pall ring is a type of classical random packing which is developed from the Raschig ring and with two layers of windows opened along its tube wall. Each layer has five ligules bending inward the axes of the ring, which is similar to the metallic pall ring and plastic. But the layer and quantity of ligules may different according to the.

Ceramic Pall Ring Ceramic Random Packing Ceramic, plastic, metal

Ceramic pall rings offer good mechanical strength as well as a non-porous surface. Ceramic is inert and iron-free, and, as a result, won't rust or react when used with harsh chemicals. We manufacture the following products: 1″ ceramic pall rings, with a 74 percent void fraction and 57.9 ft2/ft3 surface area. 1 1/2″ ceramic pall rings.

Ceramic Pall Ring

Ceramic Pall Ring for Scrubber Tower is widely applied in various packing towers of desiccation, absorption, cooling, washing and regeneration in industries of petrochemical, chemical, metallurgy, gas and oxygen generation. If ring's size is over 100mm, it is usually filled in column orderly. If its size is less than 90mm, Ceramic Pall Ring.

ACECHEMPACK CERAMIC PALL RING

Ceramic pall rings are executed with side openings which improves the separation efficiency and thus facilitate a more effective mass transfer. The pressure loss is further reduced due to moderate gas deflection. The capacity characteristics of the ceramic pall rings are more constant in comparison with the cylindrical rings, even over a.

H1 Ceramic pall ring Chemshun Ceramics

JINTAI Ceramic Pall ring is a kind of new type and high efficient packing that is improved on the basis of the Raschig ring. JINTAI Ceramic pall ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater.

Ceramic Pall Rings

Ceramic Raschig Rings, or Pall Rings, offer good mechanical strength as well as a non-porous surface. Ceramic is inert and iron-free, and as a result will not rust or react when used with harsh chemicals. Our ceramic raschig rings are manufactured for both high and low-temperature

High Grade Ceramic Pall Ring at Best Price in Pingxiang Jiangxi

The Pall Rings packaging material consists of polypropylene Bauer packaging and ceramic pall ring packaging. Pall rings packing benefits from large flows, low resistance, high separation efficiency, and wide operational flexibility. The Pall rings packing features large manufacturing capacity, strong resistance, and widespread operational.

Ceramic Pall Ring Testing equipment

Ceramic Pall ring is the advanced products of ceramic Raschig ring. Compared with ceramic Raschig ring, there are two layers of window on the cylinder wall. And each layer has five ligules bending inward. This design makes the surface area and voidage be improved and the porosity be evenly distributed. Additional, it has greater capacity and.

Pvc Pall Ring Pvc Pall Ring buyers, suppliers, importers, exporters

Ceramic Pall Ring for Separating, Cooling and Absorbing. CPR-01: Ceramic pall ring has high separating efficiency. Ceramic pall ring is a type of classical random packing, which is developed from the Raschig ring. Commonly, there are two layers of windows opened along its cylinder wall. Each layer has five ligules bending inward the axes of the.